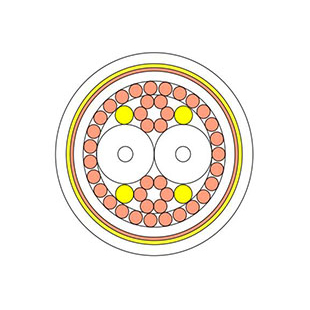

Zero Buoyancy Cable

Product Characteristics

Zero buoyancy cables have excellent characteristics such as oil resistance, corrosion resistance, acid and alkali resistance, seawater resistance, hydrolysis resistance, anti-interference, high tensile strength, anti fish bite, high safety, material saving, and cost reduction.

Application scope

The zero buoyancy cable avoids excessive sinking due to the weight of the cable itself, causing a burden on underwater equipment operations. The cable adopts a special structural design, allowing the cable to float on the water surface and be used for expansion and towing during equipment diving operations. Commonly used for power, signal transmission, or signal control connection of underwater equipment, it is mainly applied to mechanical equipment for underwater operations such as underwater robots, underwater detection, underwater construction, underwater cameras, and underwater monitoring.

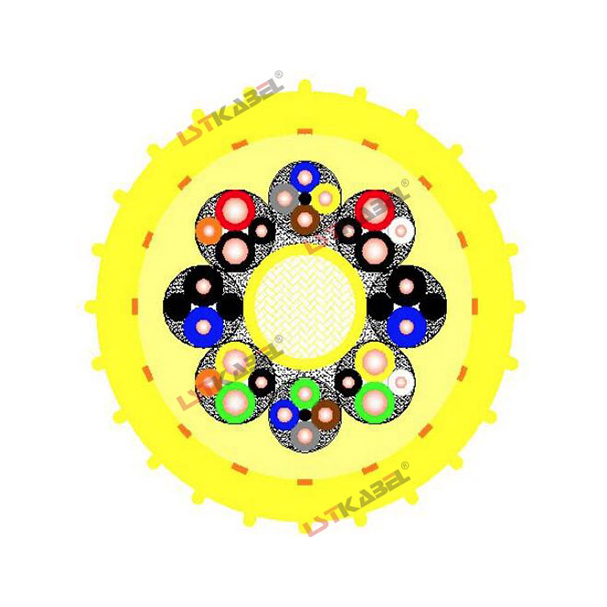

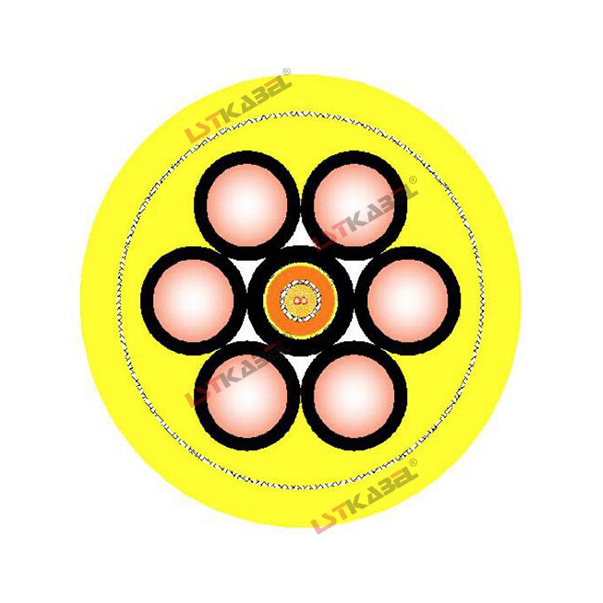

product mix

1. The DC resistance of the finished cable conductor (Class R) (in accordance with GB3956 regulations) shall refer to Appendix A Table 2;

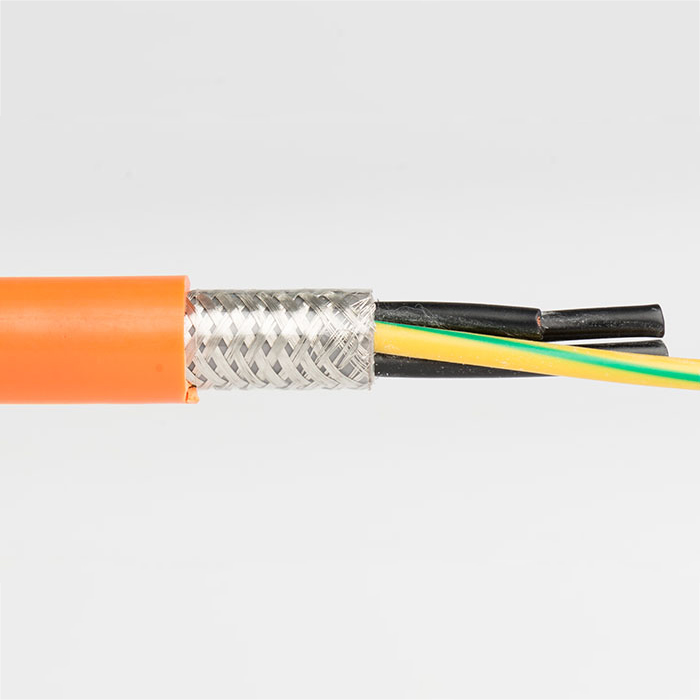

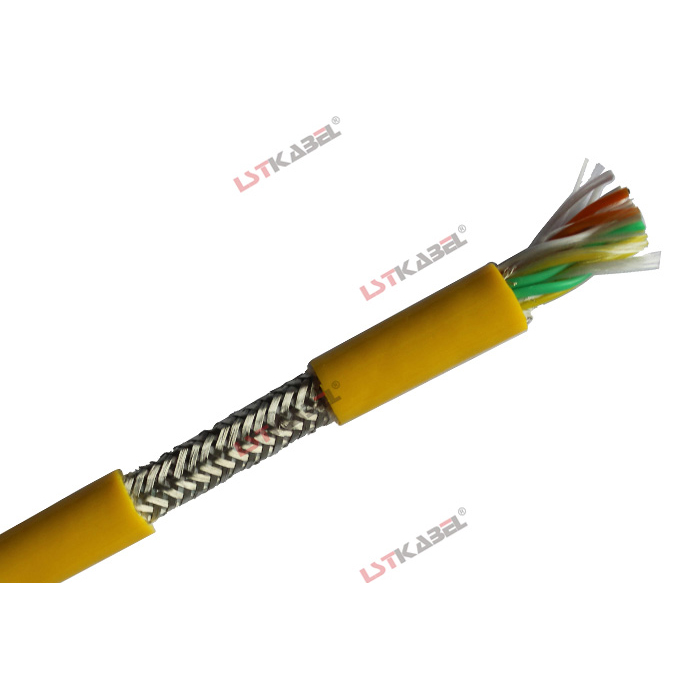

2. Adopting imported specialized waterproof insulation and sheath materials;

3. Special design and manufacturing processes;

4. At 20 ℃, the insulation resistance shall not be less than 50M Ω/KM;

5. The finished cable shall withstand an AC voltage test of 50Hz, 3.5 kV, and 5 minutes without breakdown.

The commonly used solid buoyancy materials for zero buoyancy cables are polyurethane foam, copolymer foam and composite foam. Their characteristics and applications are compared as follows:

1. Polyurethane foam

Characteristics: Density range 0.05-0.25g/cm ³, The working depth shall not exceed 200m;

Application: Pipeline floating, mooring buoys, floating boats, pipeline insulation, hose lifting ropes, short-term emergency floating materials;

2. Copolymer foam

Characteristics: Density range 0.04-0.4g/cm ³, The working depth shall not exceed 600m or more;

Application: ROV floating material, umbilical floating, pore filling for large seabed structures, pipeline insulation, submersible tank floating material, and seabed buoys;

3. Composite foam material

Characteristics: pure composite foam plastic density range 0.46-0.65g/cm ³, The working depth is the whole ocean depth, and the density range of composite foam plastic is 0.275-0.56g/cm ³, Working depth within 4000m;

Application: Widely used in deepwater fields, such as buoyancy blocks for riser devices, deepwater ROV buoyancy blocks, umbilical float, and deepwater pipeline float blocks.

description2