TRVV/TRVVP/TRVVSP Drag Chain Cable

Product Characteristics

Characteristics of TRVV drag chain cables: wear resistance, flame retardancy, oil resistance, cold resistance, UV resistance, wear resistance, flame retardancy, tensile bending life of over 6 million times, continuous core.

Application scope

TRVV drag chain cables are suitable for installation in dry or humid indoor environments, with strong stress relief or forced guidance for free continuous reciprocating motion. They are also suitable for frequent bending situations in industrial environments, such as industrial automation, woodworking machinery, machine tool processing equipment, robot systems, logistics transportation systems, and lifting machinery.

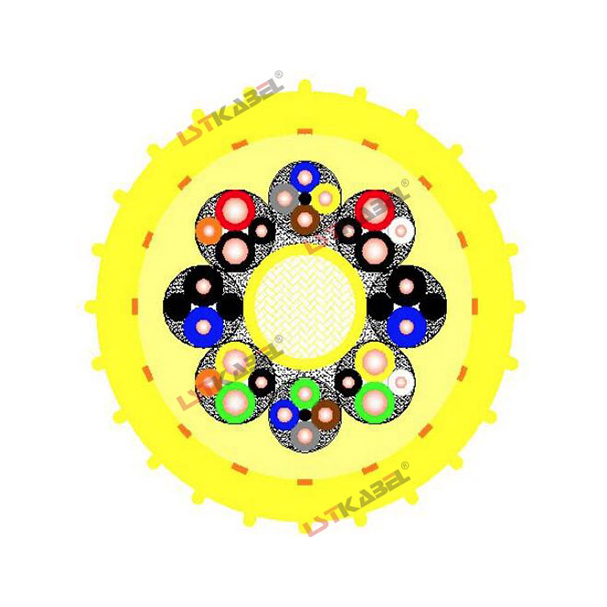

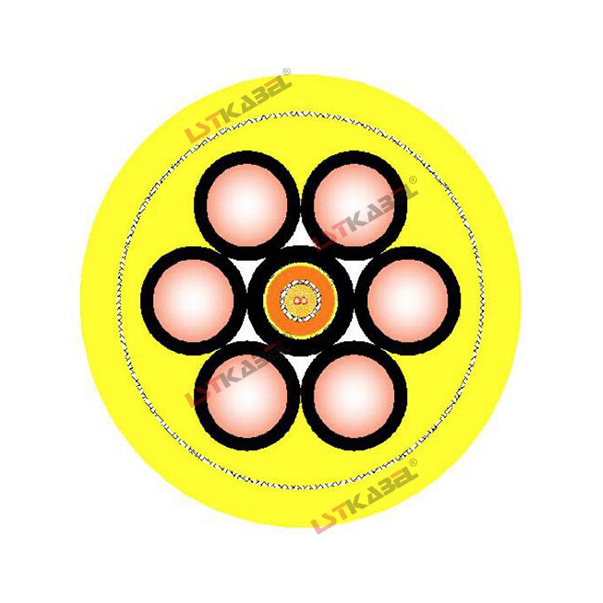

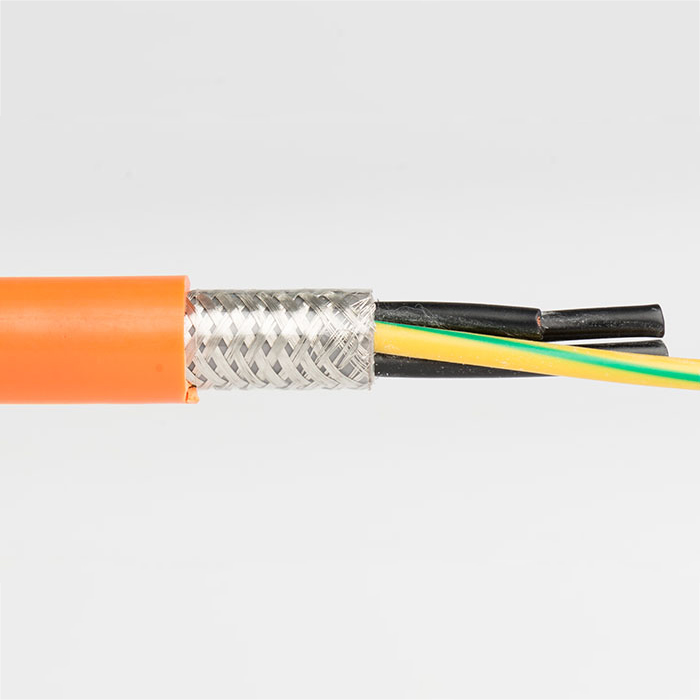

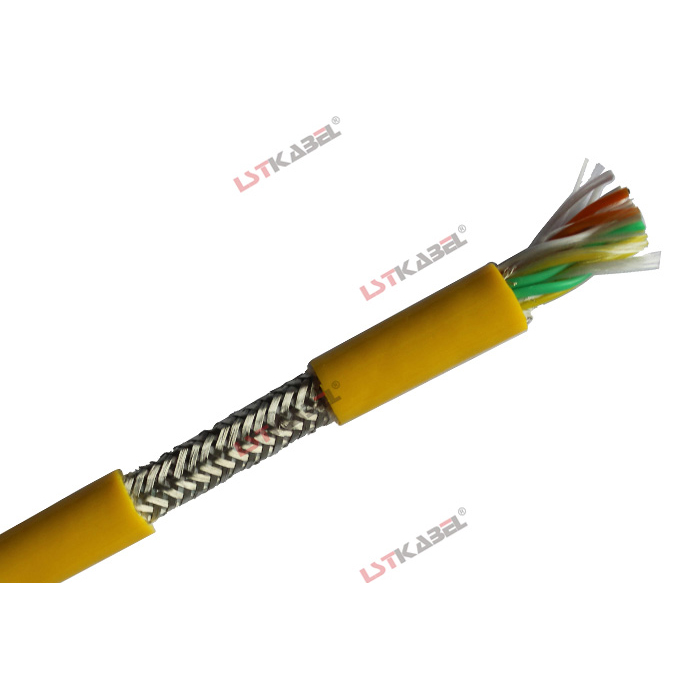

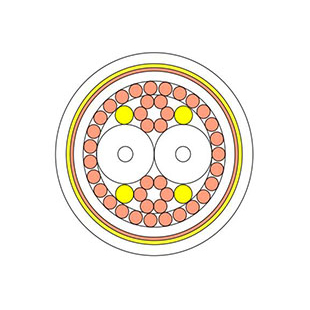

product mix

Conductor: Multi strand ultra-fine twisted oxygen free copper wire, in compliance with VDEO295 Class 6 standard.

Insulation: Ding Qing mixed elastic material, TPE mixed material, PUR (as specified by the customer).

Color: ≤ 0.5mm Color representation: brown, black, blue, red, purple, white, orange>0.5mm Color representation: black number, white code number, 3 or more cores with yellow green grounding wire (optional yellow).

Sheath: Ding Qing mixed elastic material, TPE mixed material, PUR or PVC (as specified by the customer).

Colors: black, gray, orange.

Rated voltage: Cross section ≤ 0.5mm2; 300/300V,>0.5mm; 300/500V.

Test voltage: 2500V.

Temperature range for use: Fixed installation: -30 to+90 ° C.

Mobile installation: -15 to+90 ° C.

Minimum bending radius: Fixed installation 5XD (cable diameter).

Mobile installation: When the stroke is less than 10 meters, the bending radius is 7.5xD.

When the travel distance is greater than 10 meters, the bending radius is 10xD.

description2