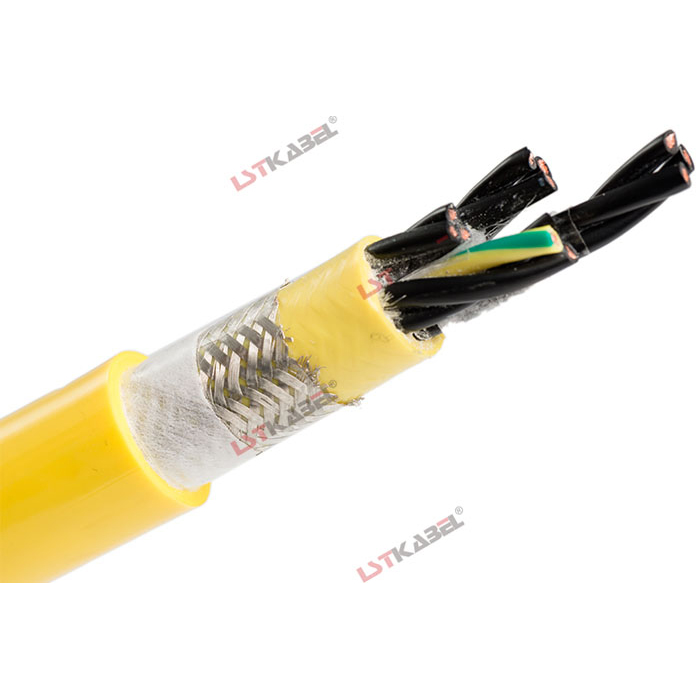

PUR Shielded Drag Chain Cable

Product Characteristics

Halogen free, waterproof and microbiological, oil resistant and coolant resistant.

Radiation resistance, oxygen resistance, weather resistance, acid and alkali resistance, solvent resistance.

High wear resistance, scratch resistance, and heavy mechanical loads.

Resistance to bending and torsion. Excellent electromagnetic performance (anti-interference).

Application scope

PUR shielded drag chain cables are suitable for installation under continuous reciprocating motion, especially in frequent bending situations in industrial environments, such as modern mechanical standard components in drag chains, logistics systems, control systems, mechanical automation systems, etc. Places that require shielding for indoor and outdoor environments such as CNC machine tools, electronic equipment, hardware stamping, wood and stone machinery, glass and door and window machinery injection molding machines, mechanical (human) hands, construction machinery, heavy-duty machinery factories, automobile manufacturing, lifting and transportation equipment, automated warehouses, docks, fire trucks, etc. Specially used in harsh environments such as heavy machinery loads, coasts, ports, wilderness, high and low temperatures, and high pollution.

product mix

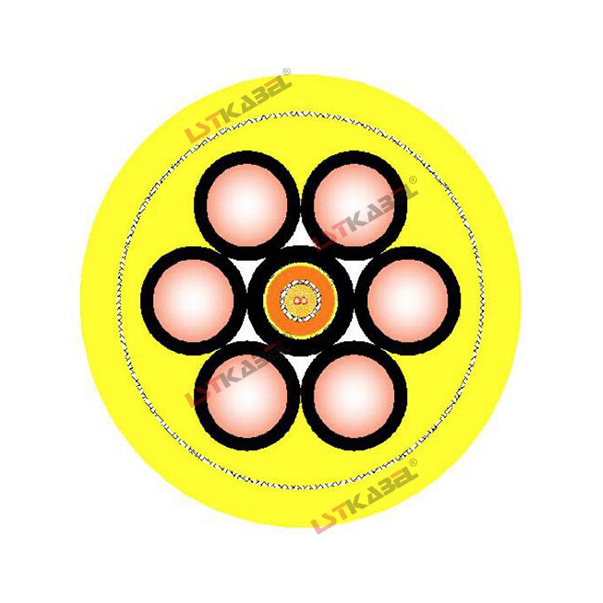

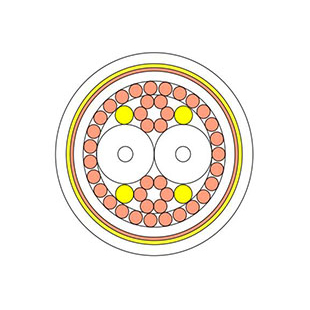

Conductor: Multi strand ultra-fine twisted oxygen free copper wire, in accordance with CDEO295CLASS 6 standard.

Rated voltage: Section<0.5mm2: 300/300V Section 20.5mm2: 300/500V.

Insulation: Special mixed TPE insulation.

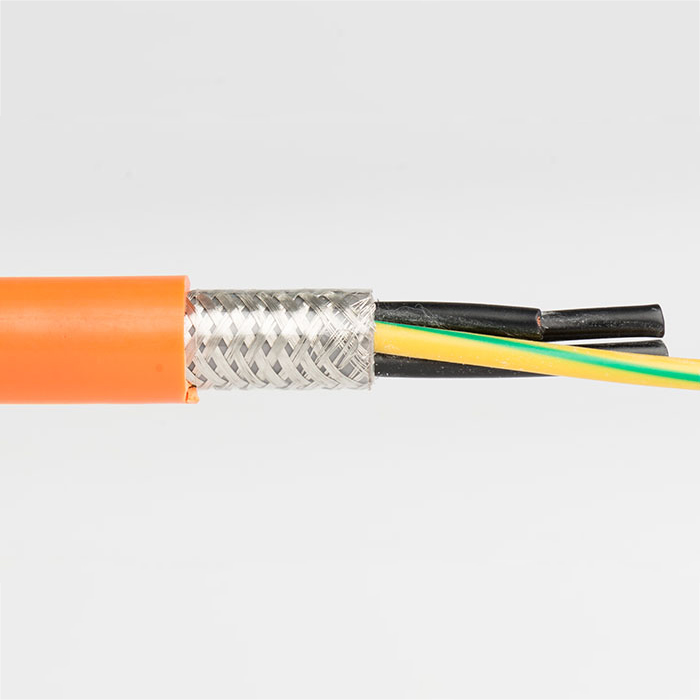

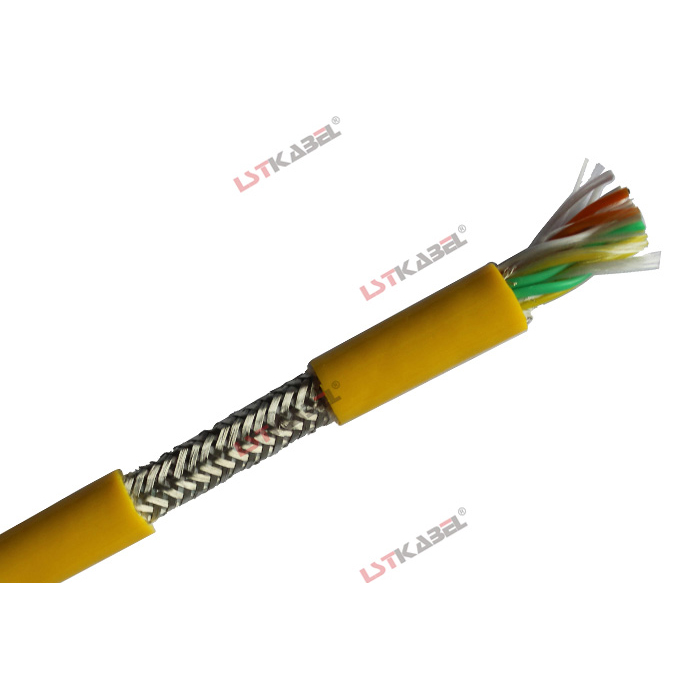

Shielding: Tin plated copper mesh woven shielding, weaving density above 85%.

Test voltage: 2000V.

Fixed laying: 6xD.

Mobile installation: When the stroke is less than 10 meters, the bending radius is 10xD, and when the stroke is 210 meters, the bending radius is 12xD.

Color code: 0.5mm black and white number, with a yellow green grounding wire for 3 or more cores (yellow green optional).

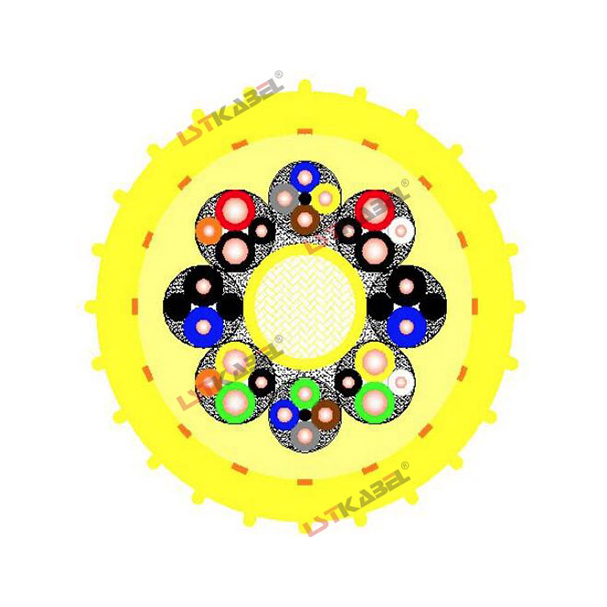

Core wire structure: anti twisting layering, or group gap filling.

Fixed installation using temperature: -45 ° C to+90 ° C Mobile installation: -35 ° C to+90 ° C.

Outer sheath: Special modified PUR sheath Inner sheath: Modified low viscosity strong extrusion inner sheath, TPE material, oil resistant.

Sheath material:

Radiation resistance: 5x107cJ/kg.

Flame retardancy: in accordance with IEC60332-1-2+EN60332-1-2.

Sheath color: Outer sheath: Black (RAL9005)/Grey (RAL7001)/Orange (RAL2003).

Oil resistance: refer to the oil resistance table.

Chemical resistance: refer to the chemical resistance schedule.

Numerical stroke:>100m, acceleration 50m/S2, movement speed 8m/S.

Bending life: 45 times/minute>6 million times.

description2