Multi cores Grouping Twisted Reeling Control Cable

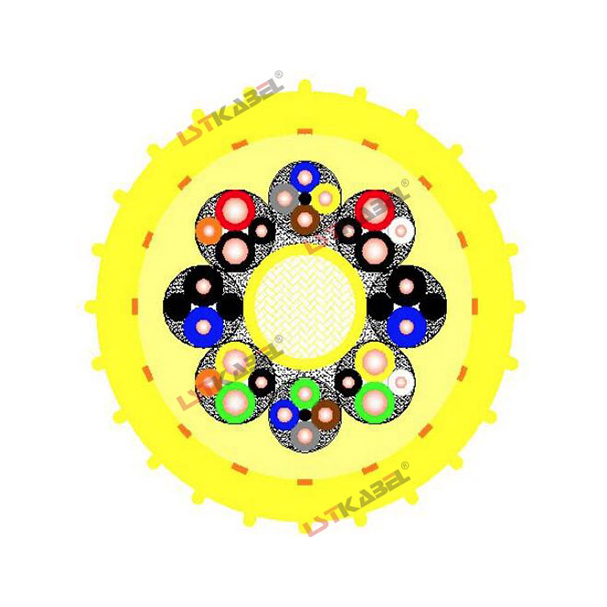

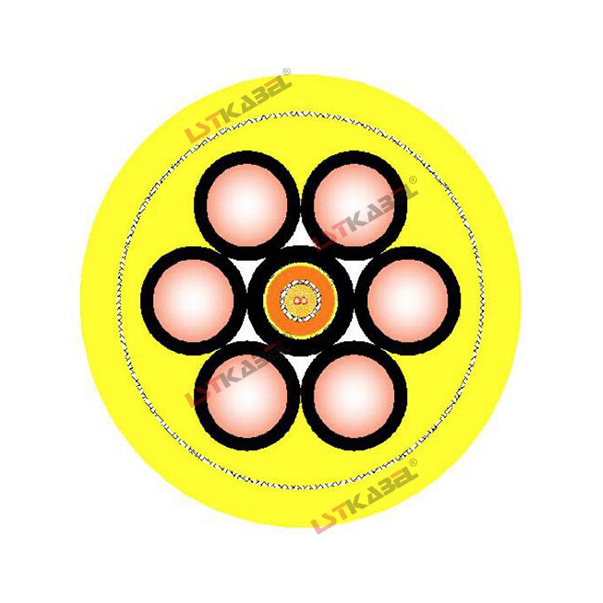

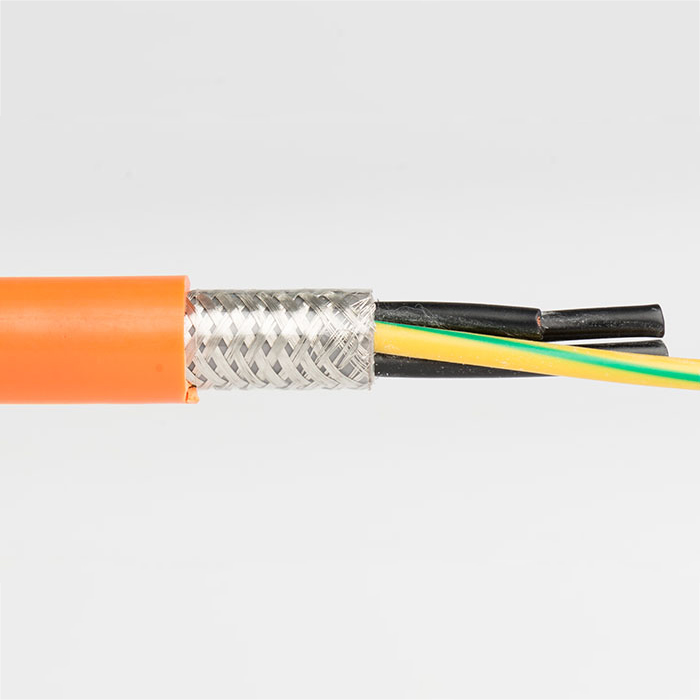

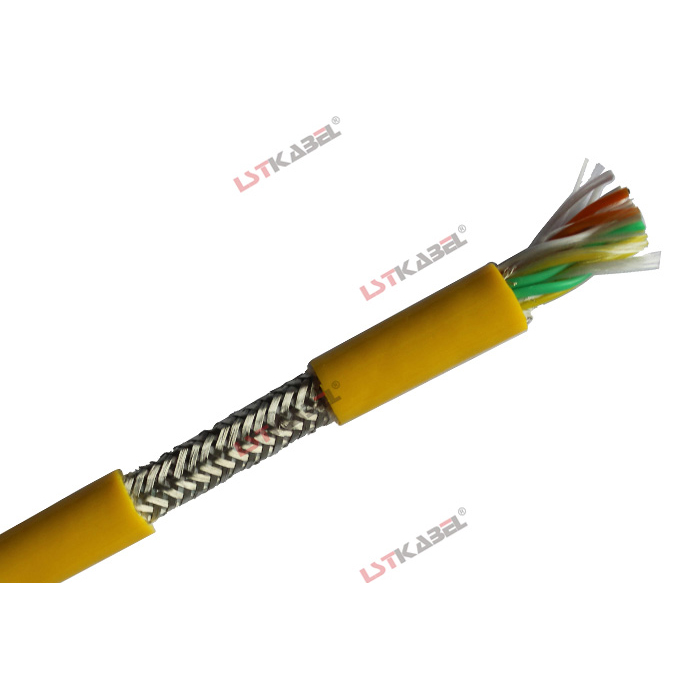

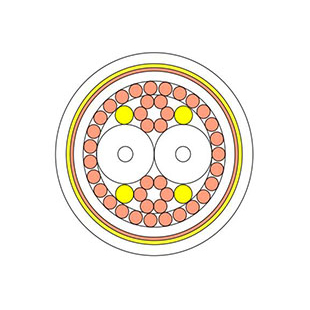

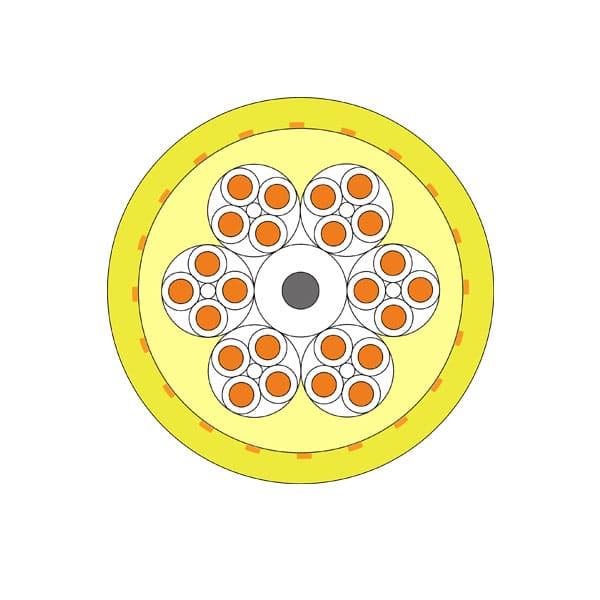

Constriction

- Conductor : Extra fine bare copper conductor class 6 VDE 0295

- Insulation: Special rubber compound based on NBR

- Filler: Tensile element filler, reinforced central support

- Inner Jacket : Special rubber compound based on NBR/PUR/others

- Reinforce : Anti-torsional Kevlar braid

- Outer Jacket: PUR/Special rubber compound based on NBR/others

- Other Structure Can Be Customized As Your Need

Technology Date

Specification(mm2) |

Overall Diameter(mm) |

Approx Weight(kg/m) |

Tensile Load(N) |

Current at 30℃(A) |

Max. resistance of the Current at 30℃ (Ω/KW)) |

18*1.0 |

19-22 |

0.490 |

1567 |

12 |

20.27 |

24*1.0 |

21-24 |

0.602 |

1690 |

12 |

20.27 |

36*1.0 |

26-30 |

0.902 |

1935 |

12 |

20.27 |

18*1.5 |

22-25 |

0.648 |

1748 |

16 |

13.83 |

24*1.5 |

25-28 |

0.847 |

1931 |

16 |

13.83 |

36*1.5 |

30-34 |

1.265 |

2297 |

16 |

13.83 |

18*2.5 |

27-30 |

0.974 |

2116 |

25 |

8.295 |

24*2.5 |

30-33 |

1.269 |

2422 |

25 |

8.295 |

36*2.5 |

36-40 |

1.895 |

3032 |

25 |

8.295 |

Voltage Class & Temperature Range

Voltage: 0.6/1kv customized

Test voltage: 3.5kv/5min (AC)

Fixed: – 50 ℃ ~ 125 ℃ Mobile installation: – 30 ℃ ~ 90 ℃

Bending radius

Fixed: 5 * cable outer diameter

Mobile installation: 6-10 * cable outer diameter

torsional Stress: ±30°/m

Cable Character

Flexibility, wear resistance, oil resistance, weather resistance, acid and alkali resistance, tensile strength, anti ultraviolet, notching resistance, tearing resistance, torsion resistance, flame retardant (optional), etc. Special cabling technology is adopted to ensure the physical stability of the core components of the cable. Full extrusion process is adopted to ensure that the core wire and sheath are not separated during the winding process.

Other structures can be customized as your need.

description2