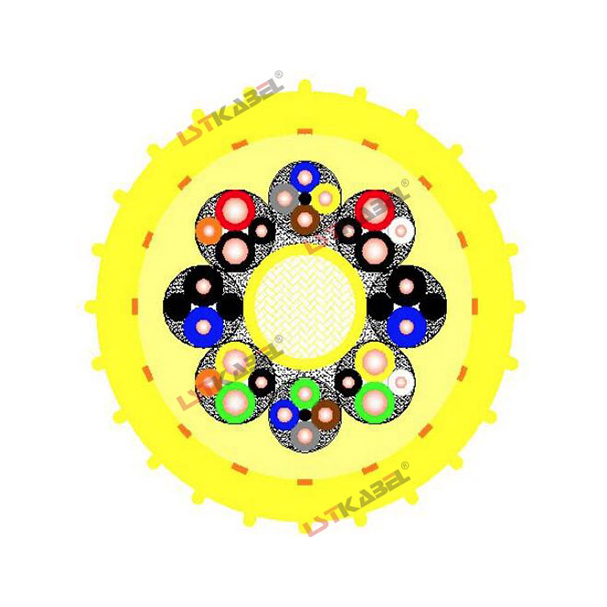

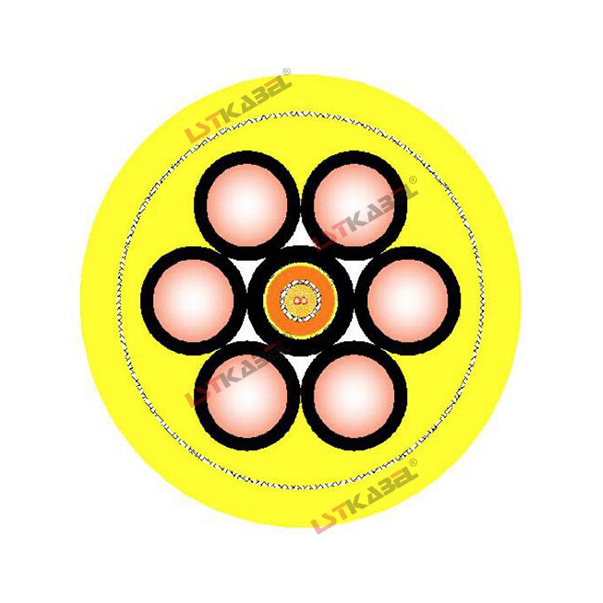

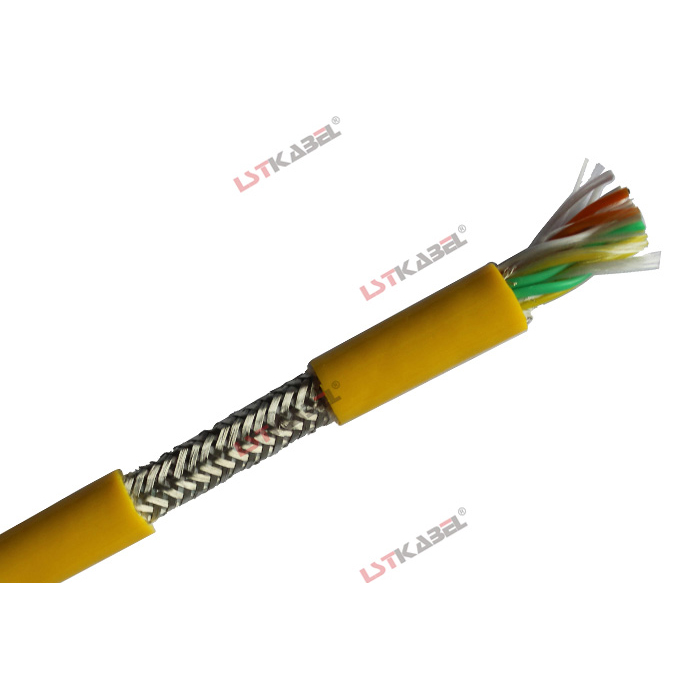

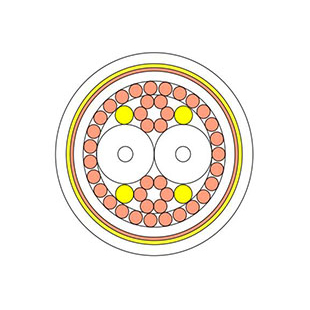

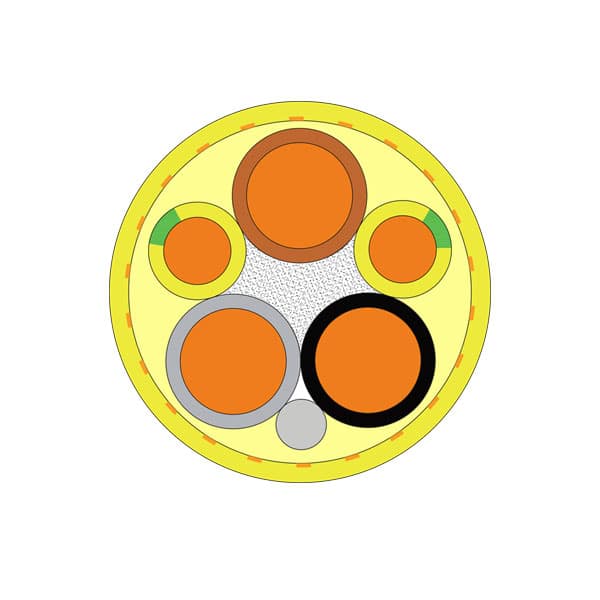

Kevlar braided crane cable with galvanized steel rope enhance cable

Reeling Cable Description

It designed specifically for drum reeling application on anything from dockside cranes to automated conveyor systems. Good UV and weather resistance make the cable suitable for exposed outdoor installation. A special good wear resistance, torsion resistance cable with high tensile support elements are also better for long time using.

Suit for high mechanical stress mobile equipment which uses the drum reel, such as crane system, handling equipment, large mobile equipment, electric-excavator, mining equipment and so on.

Technical Date

Specification(mm²) |

Overall diameter(mm) |

Approx weight(kg/m) |

Tensile Load(N) |

Current at 30℃(A) |

Max. resistance of the Current at 30℃(Ω/KW) |

Voltagedrop per 100m(V) |

3*16+2*10 |

25-30 |

1.147 |

1800 |

105 |

1.258/1.985 |

26.42 |

3*25+2*10 |

27-32 |

1.463 |

2600 |

135 |

0.811/1.985 |

21.90 |

3*35+2*16 |

31-36 |

1.965 |

3600 |

168 |

0.576/1.258 |

19.35 |

3*50+2*25 |

36-41 |

2.784 |

5400 |

206 |

0.401/0.811 |

16.52 |

3*70+2*35 |

42-47 |

3.826 |

7600 |

255 |

0.283/0.576 |

14.43 |

3*95+2*50 |

48-53 |

5.129 |

10000 |

318 |

0.214/0.401 |

13.61 |

3*120+2*70 |

54-60 |

6.607 |

12000 |

385 |

0.167/0.283 |

12.86 |

3*150+2*70 |

57-63 |

7.710 |

15000 |

452 |

0.134/0.283 |

12.11 |

3*185+2*95 |

64-70 |

9.661 |

19000 |

510 |

0.11/0.214 |

11.22 |

3*240+2*120 |

71-77 |

12.208 |

25000 |

606 |

0.083/0.167 |

10.10 |

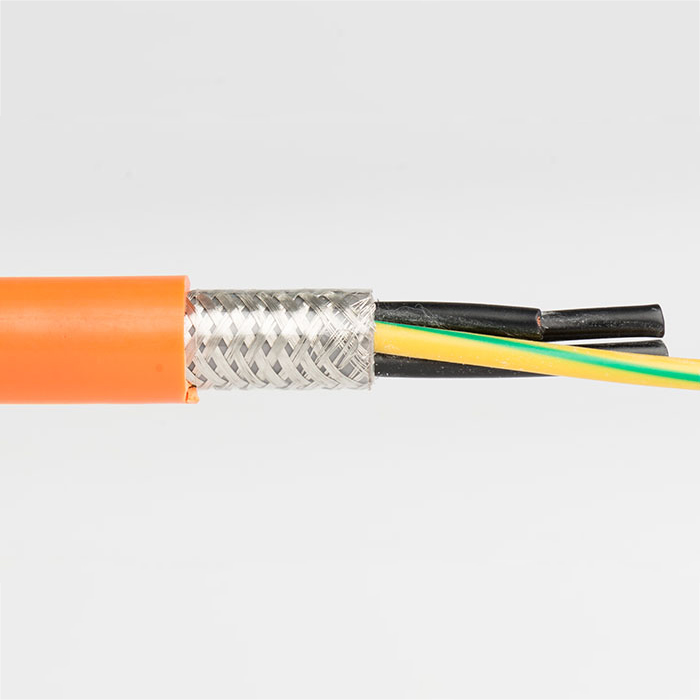

Electric Paramter

Standard:VDE0295 CLASS 6

Min. bending radius:6-10 x outer diameter

Temperature:Fix:-40℃~125℃ Remove:-40℃~120℃

Advantages:Flexible, abrasion resistance, tension resistance, Oil resistance, Flame retardant(optional), UV-Resistance

Voltage Class

Normal Voltage: 450/750V, 600/1000V Customized

Test Voltage: 3500V-5000V

Cable color Core identification: Brown, blue, black+green/yellow

Sheath: Black, gray, yellow (optional)

description2