Control and Power Reeling Cable

Structure Describtion

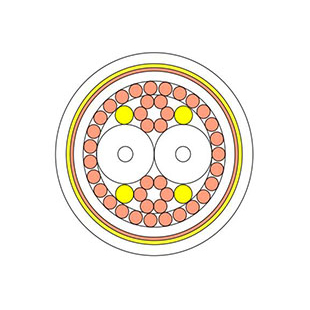

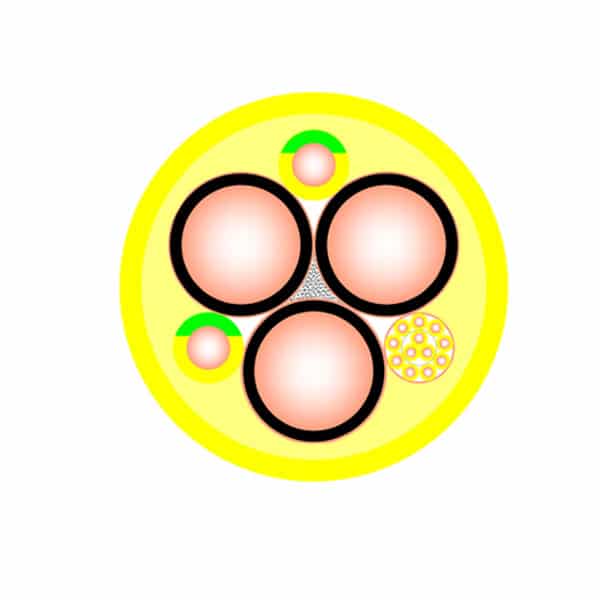

Cable Structure | |||||||||

Part |

3*185 |

2*50/2 |

12*1.5 |

||||||

Conductor |

Material |

Annealed copper wires |

Annealed copper wires |

Annealed copper wires |

|||||

Structure |

1472/0.4±0.004 |

509/0.25±0.004 |

97/0.14±0.004 |

||||||

Strand OD. |

19.8 |

7.2 |

1.6 |

||||||

Shield |

/ |

/ |

/ |

||||||

|

Thickness (mm) |

2 |

1.2 |

0.55 |

|||||

Min. thickness |

1.6 |

0.98 |

0.45 |

||||||

OD. (mm) |

23.8±0.8 |

9.6±0.5 |

2.7±0.1 |

||||||

Colour |

Black 1~3 |

Yellow/Green1-2 |

Yellow 1~12 |

||||||

Shield |

tinned copper braid |

/ |

/ |

||||||

cabling |

Fliier |

PP Rope |

|||||||

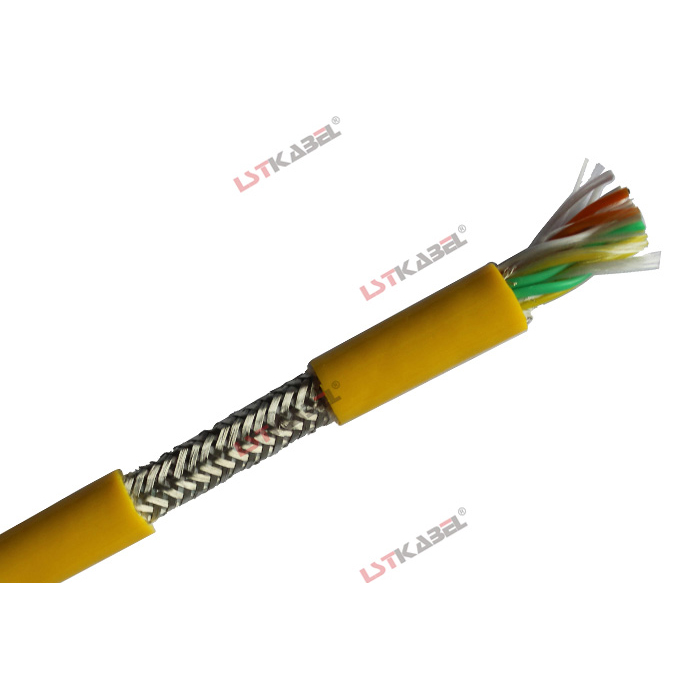

Type of shielding(wrapping) |

12*1.5 tinned copper braid shield |

||||||||

Inner Jacket |

Material |

Rubber compound based on NBR |

|||||||

Colour |

Yellow |

||||||||

Overall diameter |

57.7±1.5 |

||||||||

Total Shield |

Shield |

/ |

|||||||

Outer Jacket |

Material |

PUR |

|||||||

Colour |

Yellow |

||||||||

Thickness (mm) |

3.4 |

||||||||

Min. thickness |

2.79 |

||||||||

Overall diameter |

64.5±1.5 |

||||||||

Voltage Class

Max.DC Resistance of Conductor at 20℃(Ω/km):185mm²:0.10650mm²:0.386 1.5mm²:13.3

Rated Voltage (kV):0.6/1KV Test voltage (3500V/5min)

The temperature of enviroment under Flexing instullation:-30℃~70℃

Maximum operating temperature of conductor: 90℃

The Maximum short-circuit temperature:200

The Maximum tension(N):14500N

Cable meter weight:9.1kg/m

Bending radius:fixed:*5D flexing:*10D

description2